Volume Production of Composite Components

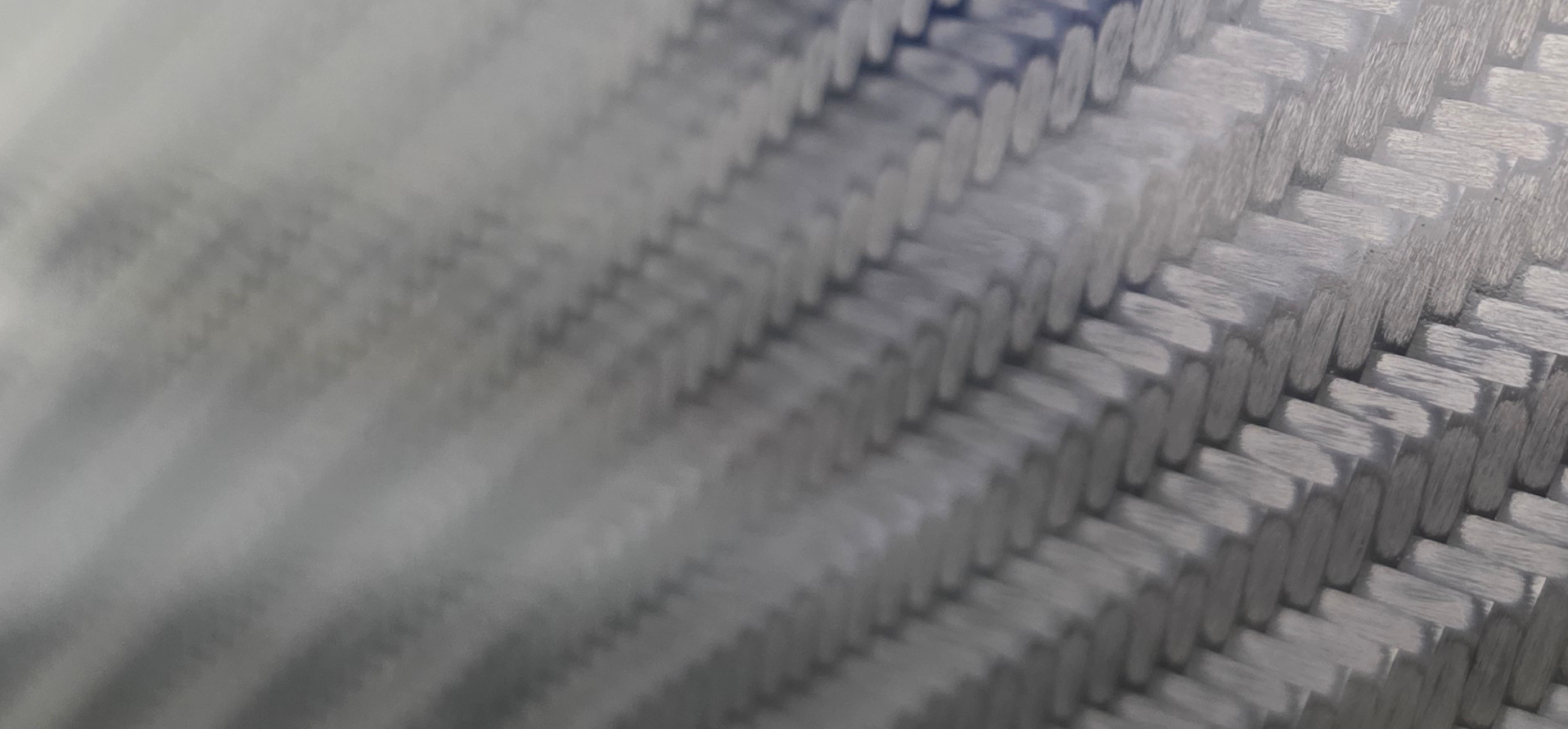

Pentaxia offers advanced composite pressing capabilities, equipped with state-of-the-art machinery to support the manufacturing of high-quality composite components. Our cutting-edge equipment allows for precise and efficient pressing, enabling us to handle a wide range of complex designs and production volumes.

This ensures consistent, reliable results while meeting the demanding requirements of industries such as aerospace and automotive.

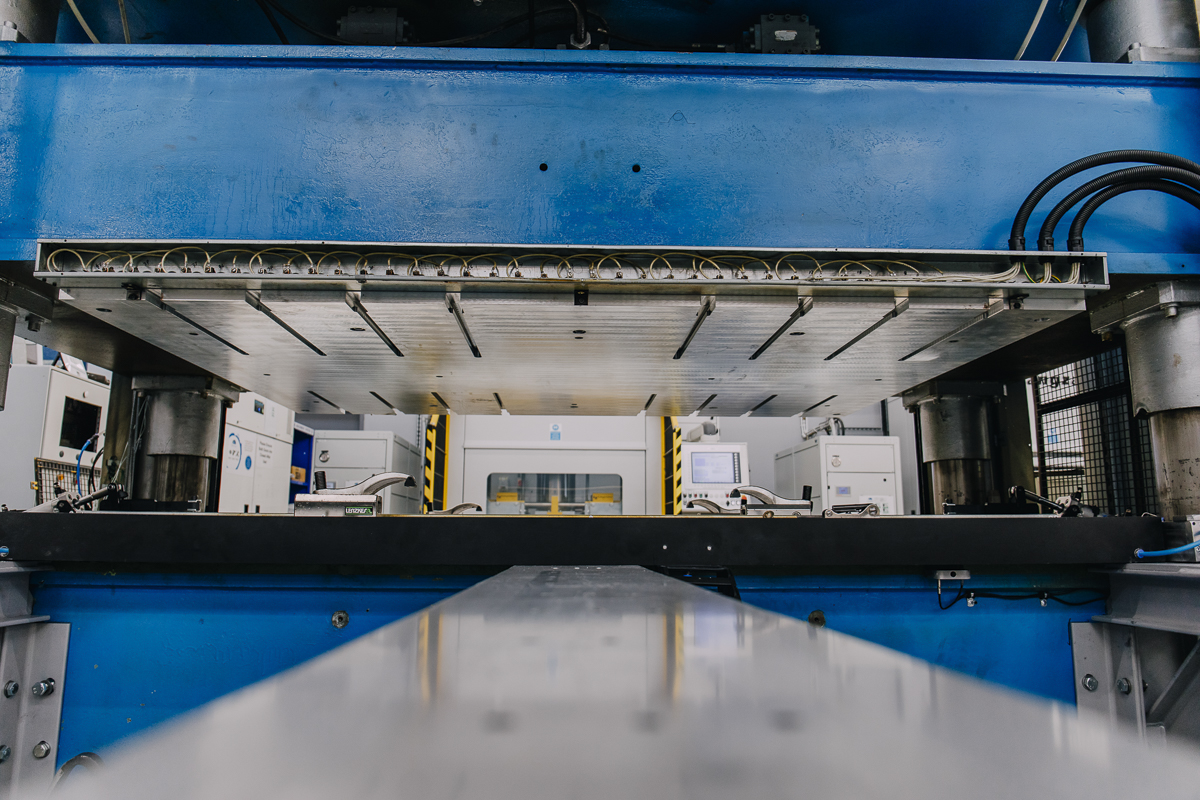

Our composite presses are utilised to produce complex aerospace composite press tooling components. The composite press moulding process enables faster cycle times which is better suited to volume production.

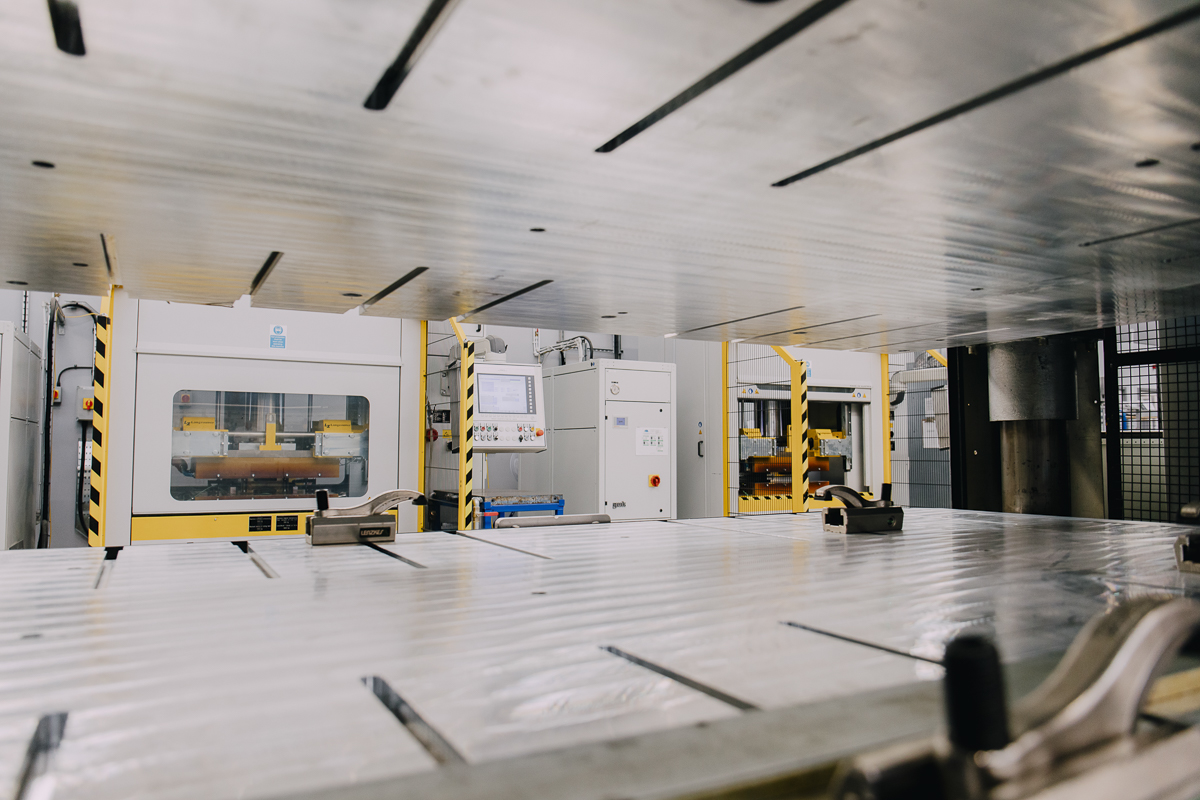

We have a dedicated production unit for manufacturing pressed components. Our modern facility is fully equipped with a dedicated pre-forming room and storage facilities for kitted prepreg and preforms.

We work closely with our material suppliers to ensure we remain at the forefront of composite press prepreg manufacturing. We can also offer “snap cure” prepregs, requiring very short press cure cycles