Quality Control Technology

Our Quality Team has over 60 years combined experience across many industry sectors. Our continual investment ensures we have the necessary systems, controls and procedures in place to facilitate continued expansion without compromising our customer quality expectations.

Pentaxia is committed to delivering composite materials, tooling and components that fully comply with all statutory and regulatory requirements. We strive to ensure that every product meets the highest quality standards, adhering to industry best practices and customer specifications, all while maintaining efficient and reliable production processes.

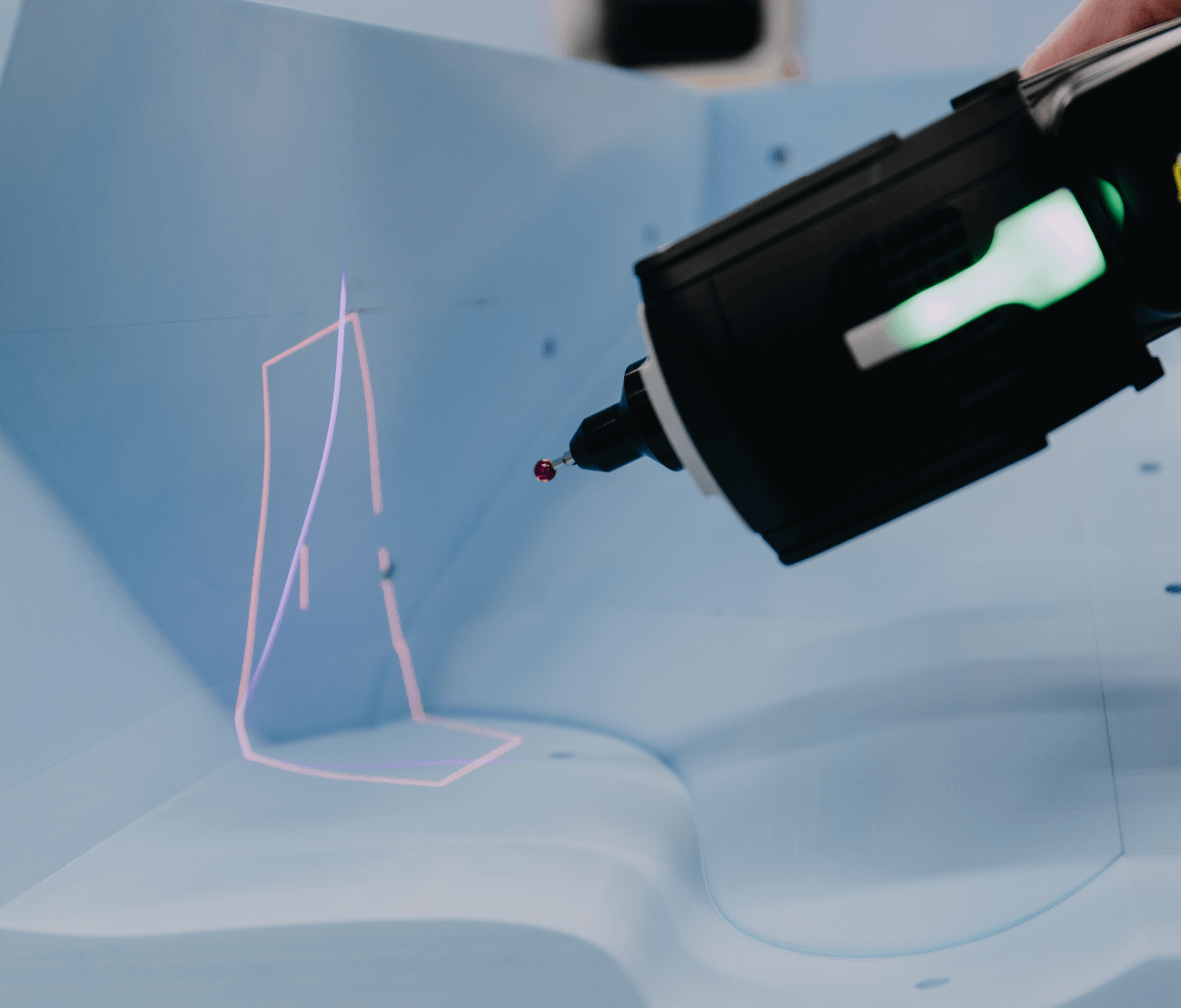

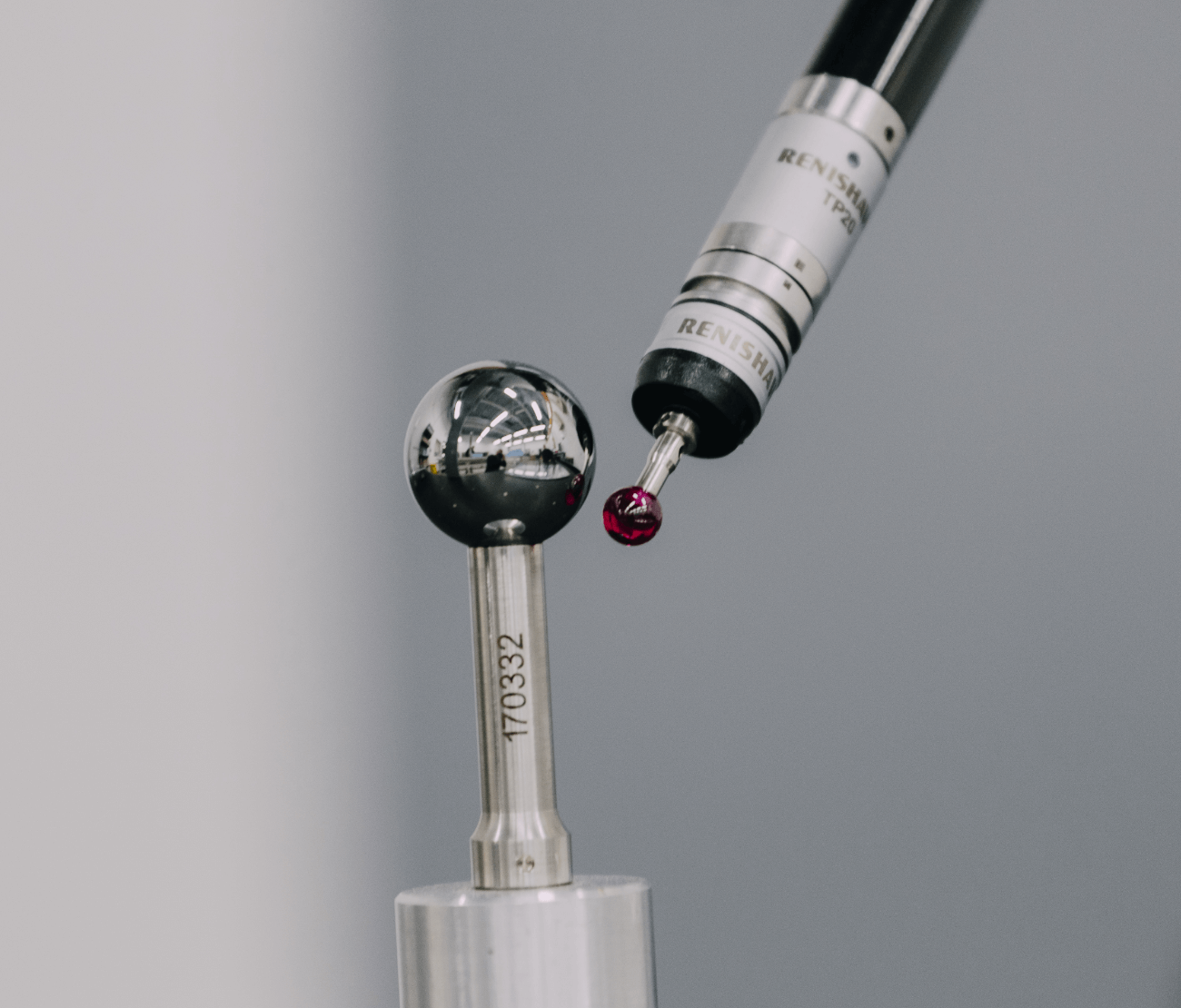

Dedicated Inspection and Quality Facilities:

Manufacturing complex tooling requires exceptional Quality and Inspection process control and we have developed a solid reputation in the composites market for manufacturing world-class tooling solutions.

At Pentaxia we are proud of our capabilities and would be happy to share our expertise. If you would like to discuss future projects, please get in touch as we aim to exceed your expectations in all aspects of our manufacturing approach.